We are the Kalai Aqua Solutions is products in Ro Iorn Remover, Softner & Auto Water Level Controller, Commercial Ro, Industrial Ro, WTTP Water Transplant and Dosing Pump in our products Water filter Retail Service for Kelvinator is a Disteributer.

Hard water is frequently unsuitable for many industrial and domestic purpose. When water is referred to as 'Hard' it simply means, that it contains excess of calcium (Ca) and magnesium (Mg) Ions than normal water. Carbonate hardness is known as temporary hardness and non-carbonate hardness is known as permanent hardness. The degree of hardness of the water increases, when more calcium and magnesium ions are dissolves. These ions have their origins in limestone sediments and also from carbon dioxide which is present in all waters exposed to the atmosphere and especially in ground water. The easiest way to soft the hard water is through Ion exchange process

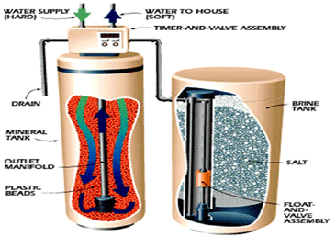

Water Softening Process

- Softening is the ion exchange process, it is done through resin, the most common and probably the easiest method of removing hardness (that is calcium and magnesium) from water and suitable for utility purpose.

- As the name implies ion exchange is a process in which undesirable ions are exchanged for more desirable ions. The softening process consists of passing raw water containing hardness through a bed of cation resin in sodium form. The hardness ions Ca & Mg are taken up by resin and in exchange, the sodium ions are relinquished from the resin. This is called the service cycle, where the hard water is being softened.

Regeneration Process

- Raw water will continue to get softened till the resin gets exhausted. Bringing back the resin to it original form is called regeneration. Softener resin is regenerated by sodium chloride- Nacl (Common salt) solution.

- The common salt solution is kept in the regeneration tank. During the regeneration process, salt solution is injected by the ejector tube into softener.

- The Nacl (salt solution) replaces ca, Mg (Hardness) from the resin, the regeneration is done every day or every few days or every week depending upon the usage and design of the water softener plant.

Models

- Our NATSOFT water softener plants are comprises of Mild Steel /SS / FRP Pressure Vessel, regeneration tank, ejector assembly, frontal piping wok with manual / Automatic multi port valve butterfly valve / conventional valves for easy operation and control. Available from 1,000 Liters/hr. to 1,00,0000 Liters / hr.

Macro Filters has been historically used for removal of odor, removal of color pigments from water. Further, our expertise lies in making available both Domestic and Industrial models of Activated Caron Filter, it also used as per treatment system in RO plant (ROP) and post treatment system in Waste water treatment plants (STP & ETP).

Macro Filters offered by us are used for eliminating bad taste, odor as well as chlorine residue in water. This excellent filter media has carbon granules of high iodine value that helps contaminants to get adsorbed to surfaces of carbon particles

PROCESS DESCRIPTION :-

- The water passes through the Macro Filters filter, the filter media consist of activated granular carbon. Macro Filters adsorbs onto its surface free chlorine, organic compounds, colour and odour. The Macro Filters bed is supported by a multilayer graved bed. The Macro Filters bed is also backwashed at fixed intervals to dislodge any accumulated dirt particles.

BACK WASH :-

- As the filtration progress the filter media gets loaded with the retained particles, this results in a continuous increase of pressure drop across the filter, when a predetermined pressure drop level is achieved the filter is shut down for cleaning. The filter media is cleaned by backwash system. After backwashing the filter is rinsed with raw water and after the required quality of water is achieved the filter is put back into service. Depending on the filtered water quality required backwashing is either done with raw water or with filtered water.

Models

- Macro Filters plants are comprises of Mild Steel /SS / FRP Pressure Vessel, Frontal piping wok with manual / Automatic multi port valve butterfly valve / conventional valves for easy operation and control. Available from 60 Liters/hr. to 10000 Liters/hr.

Need an RO purifier but worried about the cost of the purifier and its expensive maintenance costs? you keep these worries at bay. introduces Kalai Aqua Solutions Domestic RO. It is power packed with features, suited to meet your exclusive needs.

Kalai Aqua Solutions Domestic RO is provides a 6 stage purification system, that turns hard water upto 1800 ppm TDS into soft and sweet water.

- Pre-Sediment Filter Removes fine and coarse particulate impurities/dirt and improves the life of the carbon Filter.

- Pre-RO Carbon Filter Removes chlorine and harmful pesticides. It also adsorbs bad taste and odour

- Post-Carbon Sediment FilterRemoves remaining fine and coarse particulate impurities/dirt and improves the life of RO Membrane.

- RO Membrane Removes dissolved salts, hardness, pesticides and heavy metals like arsenic, lead and mercury. It also removes microbial contaminants like bacteria, virus, protozoa and cysts.

- Micro Filtration (MF) Membrane is added Post-RO, which ensures that the water is purified not once but twice.

- Post-RO Carbon Filter Last level of purification acts as a polisher and enhances the taste of purified water.

Iron is an objectionable constituent of portable water. Iron in water impart a bitter characteristic, metallic taste and cause oxidized precipitate. Coloration of water which may be yellowish brown to reddish brown and renders the water objectionable or unsuitable for use.In addition Iron stain everything with which it come in contact. Iron exists in water in two levels. One as the bi-valent, Ferrous Iron ( Fe ++) and the second one as the tri-valent, Ferric Iron (Fe+++). The Ferric Iron generally occurring in the precipitated form.

Iron Removal Systems

- Iron forms complexes of hydroxides and other in-organic complexes in solution with substantial amounts of bi-carbonate, sulphate, Phosphate, Cyanide or Halides.

- Presence of organic substances induces the formation of organic complexes which increase the solubility of Iron. The waters of high alkalinity have lower iron than waters of low alkalinity

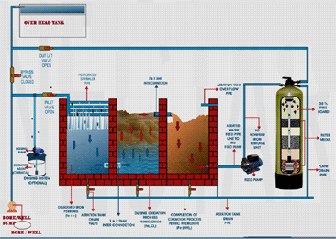

Iron Removal Process

- STAGE I - Chemical Dosing To level the pH factor, chemical pre treatment is done in order to facilitate rapid aeration, than the chemical dosed water send in to the aeration tanks.

- STAGE II- Online Aeration Type Chemical dosed water is send into the aeration tank consisting three chambers. The raw water is allowed to sprinkle at the first chamber through specially designed perforated pipes. The water travels from first chamber to other two chambers through accurately designed multiple vents at variable levels of the bifurcate walls, thus provides ZIG ZAG motion. When the water reaches the third chambers the dissolved iron gets oxides and become suspended iron particles.

- 8 Hours storage aeration Type Chemical dosed water is pumped in to aeration tank. The raw water is allowed to sprinkle (at the tank/sump) through specially designed perforated pipes and allowed to remain there for about 8 to 10 hrs to get oxidized through the natural process and the iron presence in the water becomes suspended iron.

- STAGE III - Filteration The suspended iron water is passed through Iron removal unit, the filter media is supported on gravel bed that consists of multiple layers of progressively larger sizes of Manganese Di oxide, Activated Carbon 900 IV, Graded quartz sand, Fine sand, Super fine white sand and Pebbles, which retain the suspended iron particles. During the filtration cycle the filter bed retains the dirt and suspended iron particles from the water and accumulates within the filter bed.

- Backwash As the filtration progress the filter media gets loaded with the ret ained particles, this results in a continuous increase of pressure drop across the filter, when a predetermined pressure drop level is achieved the filter is shut down for cleaning. After backwashing the filter is rinsed with raw water and after the quality of water is achieved the filter is put back into service.

- STAGE III - Filteration The suspended iron water is passed through Iron removal unit, the filter media is supported on gravel bed that consists of multiple layers of progressively larger sizes of Manganese Di oxide, Activated Carbon 900 IV, Graded quartz sand, Fine sand, Super fine white sand and Pebbles, which retain the suspended iron particles. During the filtration cycle the filter bed retains the dirt and suspended iron particles from the water and accumulates within the filter bed.